Quick Chat: Who doesn’t love a nice cold frothy one – especially when there’s bonus sustainability initiatives involved? You don’t need to feel guilty about the carbon in your carbonated beverages when you have a beer with Young Henrys.

The Green List’s Rose Mary Petrass sat down for a chat with co-founder Oscar McMahon, talking about the brewer’s solar panels, how the local community can help the hospitality industry get back on its feet, and the uses of algae in beer production (and livestock farming!).

Here is the convo.

Sydney Inner West brewery Young Henrys just got brand new solar panels to help move the needle towards net zero in their warehouses.

Can you give us a quick rundown of Young Henrys new solar panels that you got installed a couple weeks ago?

Yeah, so this project is kind of the guinea pig project for Pingala. It is their first community owned solar project. Back in 2018 they installed a 32 kilowatt system on the roof of our brewery. The set up was fantastic: it’s an awesome organisation with awesome people. We love buying renewable energy from people who are invested in the local community. So this time we fit a second 39kw system on the roof. So now, all the space of our warehouse roofs are covered in beautiful solar.

Pingala and Young Henrys have a great relationship around the two installs and have done a couple of events together as well. We are absolutely Pingala brand advocates. The concept of local people being able to invest in an affordable renewable program where they can invest in local businesses and create and use renewable energy and get a fixed rate of return is amazing.

Can you tell us about the algae project at Young Henrys?

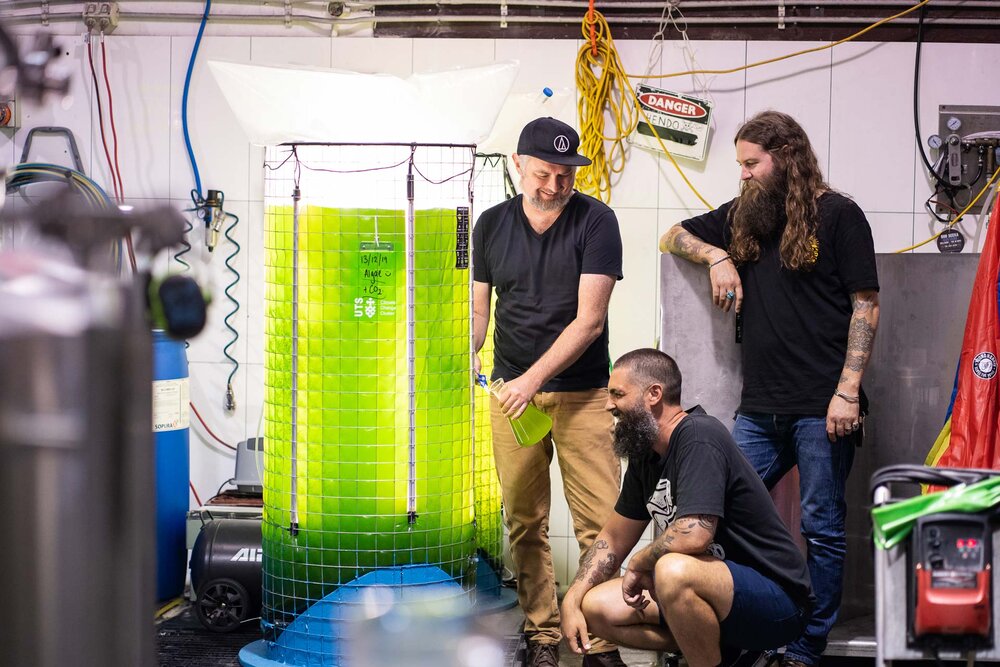

The algae project started officially in 2019. But this year will be our first prototype of a carbon-capture system. It’s a research and commercialisation project with the University of Technology Sydney. Specifically their climate change cluster. What the project has proven is that by feeding the CO2 from the beer ferment into a tank of microalgae, the algae eats the CO2 and grows oxygen.

We are all becoming algae fanatics – and that’s a sentence I never thought I’d say in my life!”

We can then reuse the algae as a feed substitute for cows, which reduces their methane emissions by 15 to 20 per cent [research has found that in some conditions feeding algae to cows can reduce methane emissions by more than 80 per cent].

We are aiming to encourage all breweries to also become algae farms in the future. The research project recently had funding matched by Meat and Livestock Australia (MLA). We are testing and finding out that not only does the microalgae lower methane emissions of cows, but it also has health benefits for cows as well. This is really exciting, this project commercialised could change the brewery and livestock industries.

The brewery has installed bioreactors in their warehouses to sequester carbon emissions. The algae “eats” CO2 and produces oxygen.

Breweries need CO2 to carbonate beer. So, any left over will be captured and used to feed micro algae tanks. Algae creates 50 per cent of the world’s oxygen – these two microreactors are 1 metre by 2 metres tall, and they create as much oxygen as one hectare of Aussie bushland. When we think of an urban oxygen creation system, this is like knocking down a whole block of buildings and replacing it with trees. That is so exciting. If we can get more breweries and wineries on board, we can create more oxygen than if their whole business was theoretically covered in trees.

Algae creates 50 per cent of the world’s oxygen – these two microreactors are 1 metre by 2 metres tall, and they create as much oxygen as one hectare of Aussie bushland.”

We are all becoming algae fanatics – and that’s a sentence I never thought I’d say in my life! But as we’re getting more into it we’re seeing more amazing projects around the world sequestering carbon, creating oxygen, creating bioplastics, food products, biogas and more. It’s an incredible space with a lot of people doing interesting things.

And can you tell me about what you do with the grain byproduct?

One of our main dry goods in beer production is malted barley grains. When we make beer we extract starchy carbs to create sweetness (maltose). After that, the use of the grains is complete. So since day one, we have donated the grain byproduct to farms.

It isn’t a complete diet for the cows, but it’s helpful as a percentage of a cow’s diet. We have always donated it to farmers – and through recent years with the droughts the farmers say that it is an important and dependable aspect to the cows’ diets.

Part of what led us to thinking about donating the algae as well, is because we’re already donating grains to become feed for the farming industry. So the algae project could be a simple add-on to that existing system. And that is pretty cool.

Brewers buy grain from the land, use the grains and then send the grain byproduct back to the farm. If we add algae into this mix in the future, that’s adding greater value to create a circular economy. We donate them because we’re getting the use of the grains and the farmers take the tons of grain from the site – we are reducing waste so they’re doing us a service.

“Beer has such a male persona, a blokey ruffian persona. But beer is incredibly fragile… The production of beer is very different to its marketing persona.” – Oscar McMahon

What other sustainability initiatives does Young Henrys have?

We installed a high-efficiency brewing system a couple of years ago, which has a “mash press” [filter system]. This has helped to increase efficiency by 20 per cent. So we can either use 20 per cent less grains or make 20 per cent more beer.

We use a steam system instead of fire so we use less materials, less water and less energy. When we add hops to the wort (malt barley extract and water), the boiling creates “isomerisation” which drops the pH balance and gives beer its bitterness and fruity zesty aroma… Basically, we’re all a bunch of nerds here.

Beer has such a male persona, a blokey ruffian persona. But beer is incredibly fragile.”

Beer has such a male persona, a blokey ruffian persona. But beer is incredibly fragile. It can’t be in contact with oxygen or light, it must be carefully handled, so we have to be fastidious. The production of beer is very different to its marketing persona.

What does your typical day look like?

A mix of meetings, emails and phone calls. I do a lot of taste testing and quality control. We’re a company of 70 or 75 people, so there’s a lot of convo’s with stakeholders. It’s really fun and no two days are the same. We have an incredible team of people who know and love what they’re doing. It’s a Monday morning and I’m pretty pumped. Which is more than you could say for most jobs.

The brewery has recently added gin to their beverage offering.

Was your business impacted by COVID?

Absolutely. We got pretty smashed up. A lot of people have heard that bottle shop sales skyrocketed in the pandemic, but pubs and bars have always been our main selling place. They make up around 60 per cent of our sales, and for the last two years that hasn’t really been there. The bottle shops have been our key for survival. We had to make big decisions – it’s been very taxing and emotional for all of us. But we are lucky to have an incredible, engaged and positive team with workplace morale intact. That’s what we’re grateful for.

How is your business doing now?

We are starting to see “green shoots”. We are seeing trade return, we saw a great weekend. We just shifted a couple people within our teams and progressing people, so we’re starting to have a positive forward motion again.

I just hope that over the next few months the hospitality industry can get back on its feet. We have all had a difficult two years, especially bars and pubs – they haven’t been able to sell to anyone. At least we have been able to sell. I just hope the industry recovers quickly, and all of us as patrons of the hospitality industry get back into it (and stay well behaved while doing so).

Our plans are for it to be the best year out of the last three years… We just want to have fun!”

Awesome! And what are your plans for after this interview?

I have about 130 emails to respond to – I’ll be chained to the computer today!

It sounds like you’re very busy, thanks so much for the chat! Do you have any other news that you want to tell people?

Nothing we can release to the public just yet – but our gin and tonic cans are hitting the shelves across the coast soon. So stay tuned.

You can read more about Young Henry’s here: Young Henrys: Making good beer with a light footprint

Check out their sustainability initiatives here: Working towards a greener future, one beer at a time

Check out citizen-led energy movement Pingala here: click here

Read about UTS’ algae bioreactor project here: click here